Luxury workshop and craft industry

A luxury workshop and an artisanal factory, these are the two “faces” of Lamberti Design. Based in Cava de’ Tirreni, at the gates of the wonderful Amalfi coast, the company has more than 50 years of history, during which it has established itself nationally and globally in the field of the design and manufacturing of metal furnishings for indoors and outdoors.

The attention to detail, the metal patinas, and the increasingly ambitious and successful projects have won the trust of its customers. Lamberti Design deals with the top “Made in Italy” brands and with well-known architecture and interior design firms for hospitality structures, shopping centers, Retails, HO.Re.Ca., and outdoor luxury furniture.

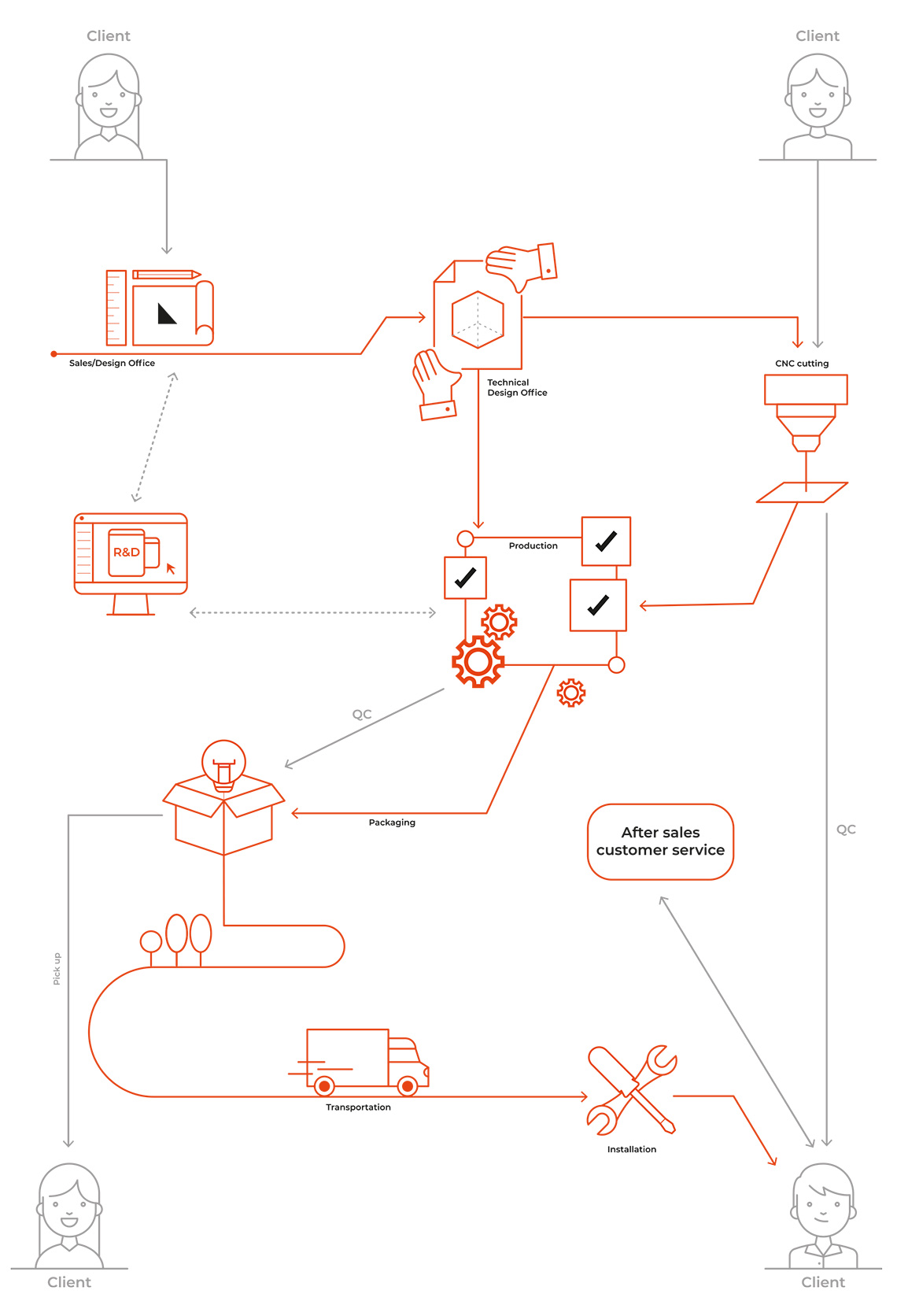

From idea to execution

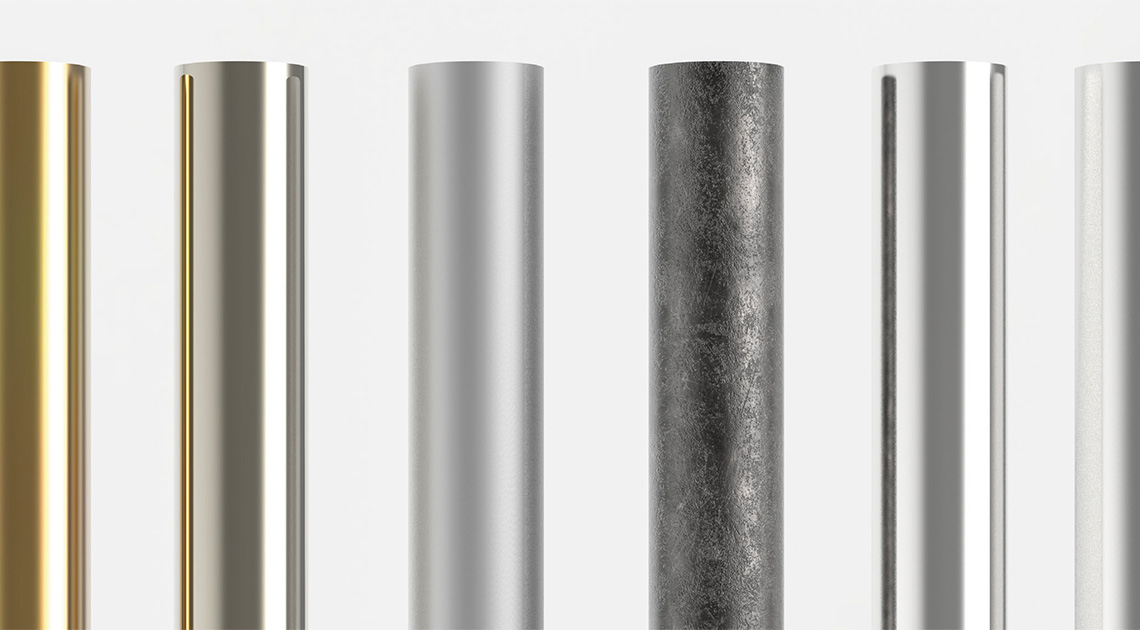

Lamberti Design has made its organization one of its strength. The technical and sales office communicate directly with the customers, gather the project’s information and transfer the shop drawings to the production. Everything aims to ensure that the entire process – from idea to execution – is fast, lean and planned. Knowledge of materials, cutting-edge technology, study of shapes and finishes are distinctive features of Lamberti Design’s brand. Investments in research and development have led to new metal patinas and finishes: range of color solutions with classic and / or trendy coating; paint finishes applied with artistic / crafty techniques with unique aesthetic results, different from the most common paints. The production flexibility allows making small, bespoke productions, where each job is assigned to a master artisan “Maestro”. Furthermore, the cnc technology allows Lamberti Design to offer also products made with a large-scale standardized production

at competitive pricing.

A look ahead to the future

The management is constantly working to improve the production organization facilitating the communication among the sales office, the technical office, the workshop, the logistics and the after-sales support. Great attention is payed to the environment and to the workers’ life quality. The new factory is the headquarters in which new collaborations with architects and designers entangles to prototype new furniture pieces for the international markets. The propeller for constant growth is the daily challenge that comes for the bespoke workmanship, as well as from the Research and Development of new metal patinas that expand the range of finishings offered.

CNC, R&D

In the new factory, which is still expanding, you can find the traditional artisanal production techniques hand to hand with the new numerical controlled machines such as the water jet and the fiber laser cutting machines, the CNC bending machine and a CNC calander machine. Everything is driven by a last generation centralized data management system. A R&D department explores new metal finishes with an adjoining painting oven.

The skills of the technical and drawing office grow. It stands out for its ability of listening, problem solving, prototyping, engineering, rendering and effective execution of customer projects.

Go Green!

The factory responds to a corporate sustainability plan, which involves the use of raw materials with low environmental impact, a phytodepuration system, and the use of alternative energy sources – such as a 400 square meters solar power plant installed in 2020. A rigorous waste management policy aims to minimize the environmental impact of production and increase recycling.

Finally

Each project, from small to large, is linked to an account from which the customer can learn all information related to delivery, logistics, cargo insurance and post-installation technical assistance.